The Biorock Non-Electric Treatment Process

How BIOROCK plants work?

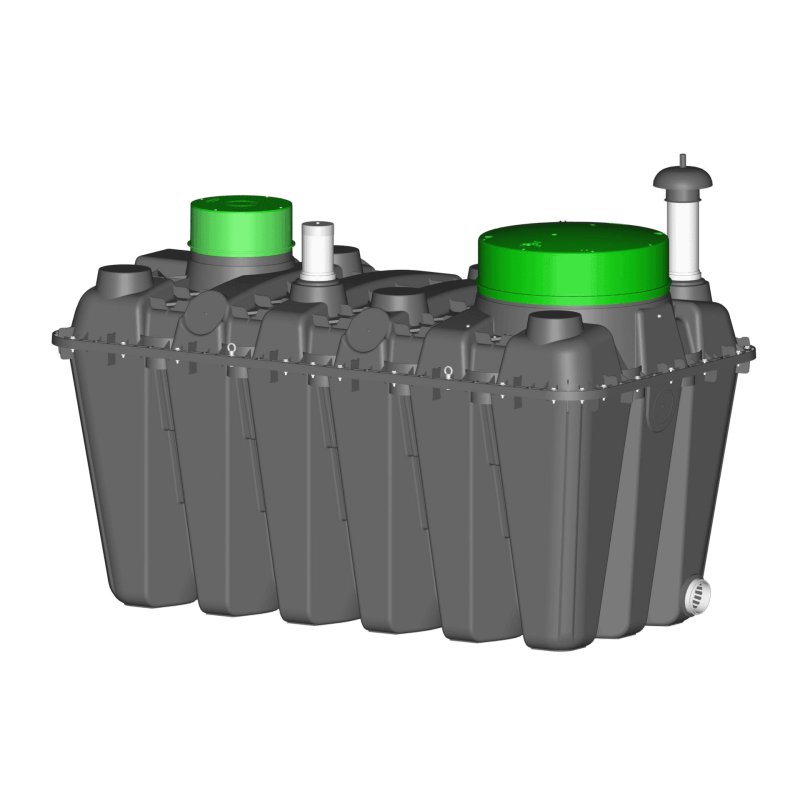

Step 1 : Primary Tank

The Primary Tank clarifies the raw sewage by dividing fats, oils, greases and organic solids. The sewage then passes through an effluent filter, before discharging into the BIOROCK reactor.

Step 2 : BIOREACTOR

The Bioreactor purifies further the pretreated wastewater with a biological process. To naturally treat the wastewater, our systems use our unique BIOROCK Media, an exclusive and very efficient carrier material for bacteria.

Step 3 : Discharge

Depending on the ground type, effluent will be discharged by gravity, or by a pump.

en

en

at

at

bg

bg

ch

ch

cn

cn

cz

cz

de

de

dk

dk

dz

dz

ee

ee

es

es

fi

fi

fr

fr

gr

gr

hr

hr

hu

hu

ie

ie

in

in

it

it

lt

lt

lv

lv

ma

ma

nl

nl

no

no

nz

nz

ph

ph

pl

pl

pt

pt

ro

ro

si

si

sk

sk

tn

tn

ua

ua

us

us

za

za